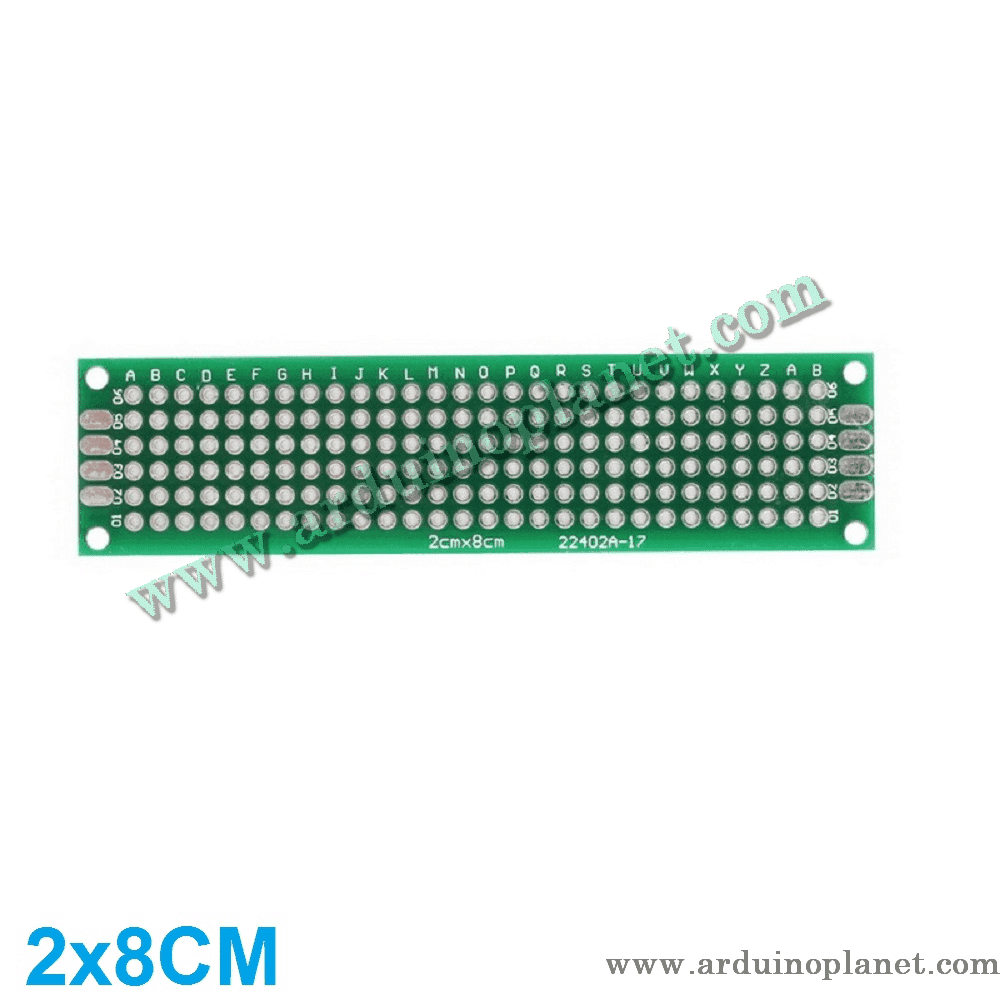

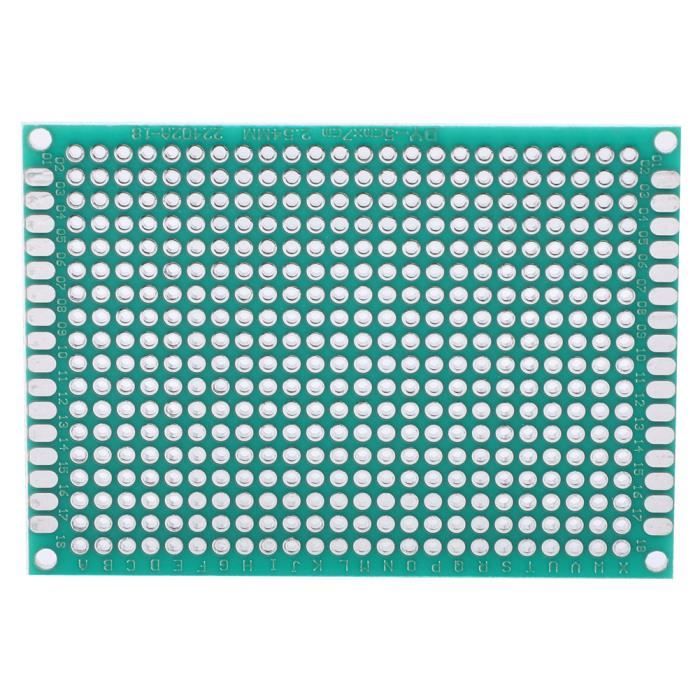

Pcb double face 2 x 8cm perforé prototype Moussasoft Maroc

Construction of double layer PCB: All the components of double layer pcb are explained below: Pad: pad is only a bit of copper on which lead of parts are mounted and on which binding are done. Pads gives the mechanical help to the segments. Trace In PCB, parts are not associated with the assistance of wires.

Double sided flex PCB Double sided flexible PCB

Double Sided PCB Double sided PCB is designed with two sides for component mounting, with copper coating on both the top and bottom layers. The two sides are separated by an insulating material, and they are connected through plated through holes. These holes allow for component connections and soldering. To enable effective circuit creation, proper […]

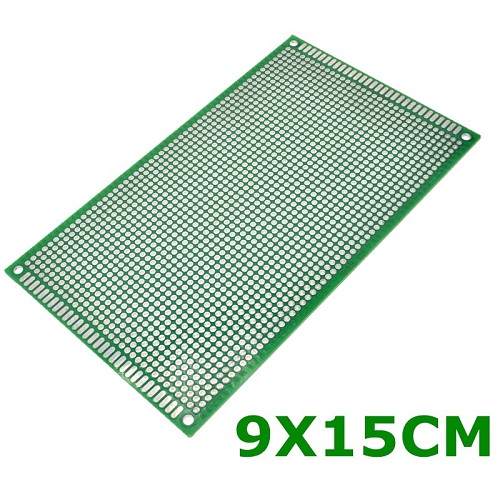

pcb double face 9*15

The advantages of using double-sided PCBs in your upcoming project include: More space for components: By having conductive layers on both sides, a double-sided PCB has twice the room for components as a single-sided PCB. Increase circuit density and complexity with ease. Numerous applications: Double-sided PCBs have the circuit complexity to.

Why break a PCB trace plane into multiple parallel traces? Electrical

ICAPE Group Double Side technical specification; Technology highlights: Double side PCB with PTH (Platted Through Hole). Peelable mask, carbon ink, bevelling, countersink, edge platting. Press-fit holes +/-0,05mm. Materials: FR4 raw material with high TG, high CTI, high performance and/or halogen-free. Base Copper Thickness: 1/2 Oz to 15 Oz.

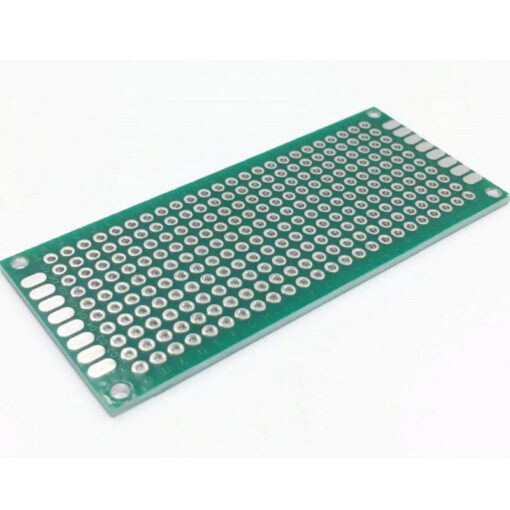

PCB double face 12 x 18 cm Shop4makers Maroc

Double Sided PCB. Double Sided PCB is a type of PCB that has conductive copper layers on both sides of the board. Simply put, double-sided PCB comes with two-sided traces or paths i.e. top layer and bottom layer. It is extremely useful in advanced electronic applications because of its small size and low cost as compared to multilayer PCB.

Circuit imprimé, PCB Double Face 2X8CM Maroc

This is a guide for milling a double sided (2-sided) PCBs with a CNC using FlatCam. $2/5pcs 2Layer & $5/5pcs 4Layer PCBs: https://jlcpcb.comIn this tutorial.

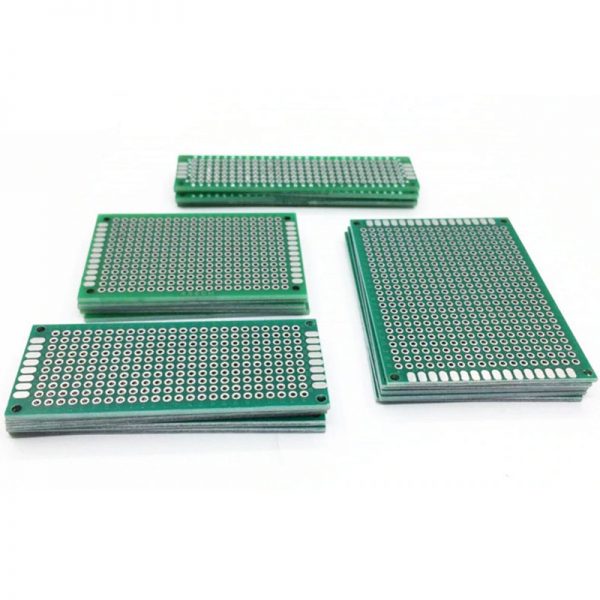

Kit PCB Double face 5x7 4x6 3x7 2x8 Shop4makers Maroc

With this video we start a short series that describe how to make double side PCBs with The Ant machine. This episode describes the gcode files generation..

09X15cm DOUBLE FACE Prototype PCB Universal Maroc Moussasoft

Single-sided PCB traces are present on only one side, while double-sided PCBs have traces on both sides with top and bottom layers. The components and conductive copper are mounted on both sides of a double-sided PCB, and this leads to the intersection or overlap of the trace. Double-sided PCBs are best for realizing high-density circuits that.

PCB double face 3X7CM perforé Maroc ARDUINO MAROC meilleur prix

Single-sided PCBs usually has conductive metal and components mounted on only one side of the board. Conductive wiring, generally of copper, is used to connect through the other side. Double-sided PCBs are a bit more complex. They have electronic components mounted on two sides and the wiring crosses over both sides.

Double sided flex PCB Double sided flexible PCB

Double Sided PCB, also known as Double Layer PCB, is a printed circuit board with conductive copper layers on both sides. JHY is a reliable PCB manufacturer, providing high-quality single-sided PCB, double-sided PCB, and up to 64 layers of multi-layer PCB prototype and mass production service. At JHYPCB, we are a leading PCB manufacturer in.

PCB double face perforé meilleur prix au MAROC

Single-layer PCB: Double-layer PCB: The thickness of single-layer PCB is 1oz, which allows it to be cut into small pieces. The thickness of double-layer PCB is 2oz, which makes it difficult to cut into small pieces and causes the processing cost to increase. Single-layer PCBs use only one layer of copper foil as an electrical conductor.

EJ.life Carte PCB double face 10 pièces 5x7 cm Double face Prototype

The double sided pcb assembly process is a complicated combination of various steps leading to the final product. These steps should be performed in a strictly defined sequence - otherwise the final product will not meet the initial assumptions. At the PCB design stage, not only the selection of the appropriate technology is important..

Circuit imprimé, PCB Double Face 10X15CM Maroc

Here is how double-sided PCB assembly is performed: First, the components on one side are assembled and soldered. Then, the board is flipped for assembly on the other side. The step-by-step process can be described as follows: Apply solder paste→pick and place components→solder components→review the assembly→test→flip the board→.

09X15cm DOUBLE FACE Prototype PCB Universal Maroc Moussasoft

Introduction to Double Layer PCB Manufacturing. Double Layer PCBs require a complex manufacturing process that needs to be understood thoroughly. They have two sides of conductive paths, separated by insulation. Preparing the substrate, designing a layout with CAD tools, etching and drilling, applying copper sheets - these are part of the process.. High precision is a must, as components are.

pcb simple face 5 x 7 cm Maroc

Creating a double-sided PCB with easyEDA. This video covers the most basics of PCB design from a complete newbie's perspective.Part of the best selling PCB.

09X15cm DOUBLE FACE Prototype PCB Universal Maroc Moussasoft

Les PCB double face permettent des conceptions d'appareils électroniques plus compactes en utilisant les deux côtés de la carte. Cela permet de réduire la taille globale du PCB, idéal pour les applications dans des espaces restreints. Les tableaux simple face limitent les options de disposition, mais le double face offre une plus grande.